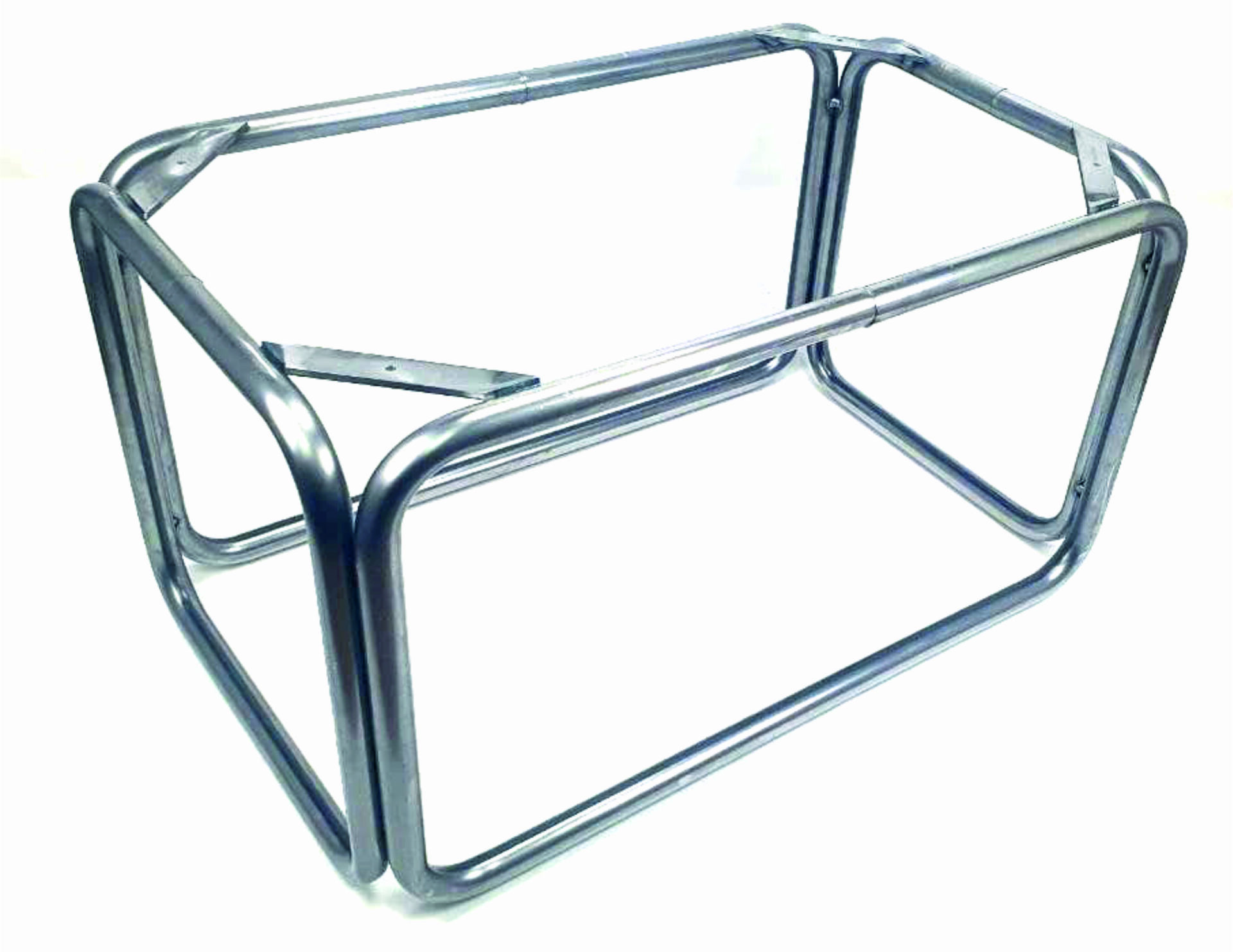

Vandema Products is specialized in processing steel pipe, solid and/or strip steel. Preferably single pieces or small series.

This page lists the operations we can perform.

We only process bare steel. No aluminum, stainless steel or hot rolled steel. Post-treatment can be done with powder coating, nickel, chrome or zinc. Ultimately, we deliver a complete end product including packaging and labelling. Everything in close consultation with the client.

By choosing our machine park, with a short set-up time, we can produce single pieces and smaller series at a realistic price. All input is welcome, from sketch to 3-d drawings. Flexibility is our top priority.

Bow

3-axis Thoman fully automatic mandrel bending machine

1-axis Amga semi-automatic bending machine

We bend steel pipe with the following dimensions:

Ø13 R=41

Ø16 R=32

Ø19 R=45

Ø22 R = 60 and R = 70

Ø25.4 R = 50.8 and R = 100

Ø30 R = 60 and R = 85

Ø32 R=142

Ø38 R=76

Ø 44,5 R=90

This with different wall thicknesses of 1.5 mm

Permit

Mig en Tig let dead 200 amps

Various EWM and Telwin equipment

Saws

Wisent fully automatic circular saw up to Ø 50mm

Bewo and Thomas hand-operated circular saws up to Ø100mm

Various operations

- Taps with tap arm from M4 to m16

- Strip bending with Digibend 16 tons

- Punching/cutting with Geka 45 tons

- Grinding/polishing pipes up to 110cm

- Deburring pipes with brush machine

- Drilling from Ø1mm to Ø30mm

- Deburring/tumbling with Kromas circular vibrating drum

- Press dimples into handlebars with self-developed hydraulic press

- Various specialist operations with self-developed machines

waltz

2-roller driven Tugra roller with 40mm axles

strip and tube in various sizes

tube Ø 38mm

tube Ø 16mm

Tube Ø 50mm